The load cell (loadcell) is a transducer that converts a force such as weight, tension, compression, pressure, or torque to a signal output that a weight indicator can measure. The strain gauge-based load cells are the most commonly used type and it outputs an electronic signal that either be analogue or digital

The Wheatstone Bridge is the configuration where the strain gauge used in

Other types of mechanical output load cells are there such as Pneumatic and Hydraulic but they are very limited in use today

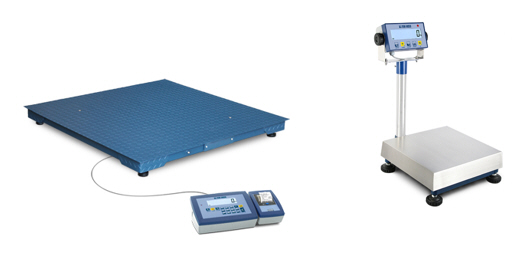

The common uses of load cells are as a weight sensor in weighing scales.

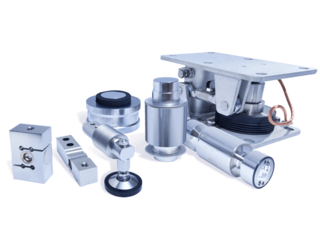

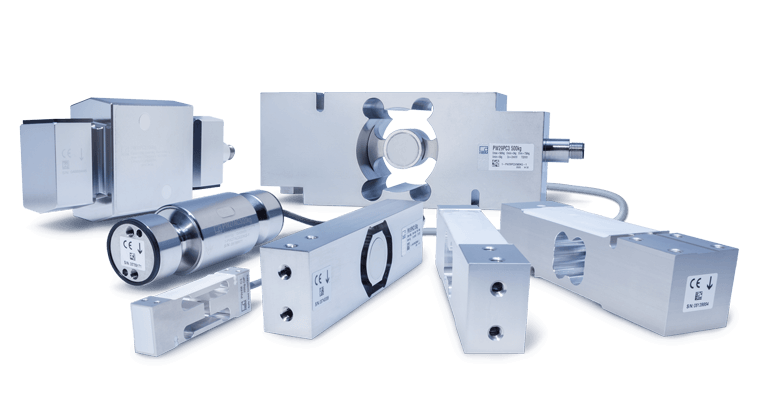

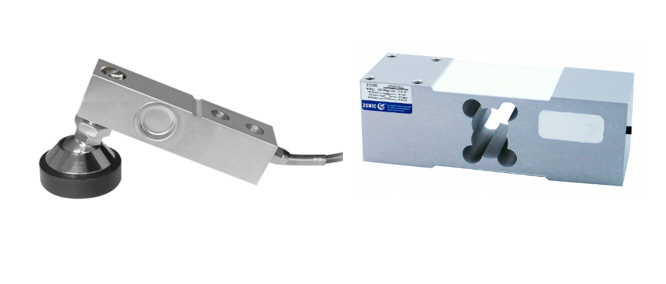

We can classifieds and categorized load cells based on many ways, such as output type (electronic, digital, hydraulic), material structure (Aluminium, alloy steel, stainless steel), or based on the application where it can be used (weighbridge load cell, conveyor belt, platform)

Here are the top load cell types for your weighing scales & application. To buy load cells visit our shop to view the available models and prices.

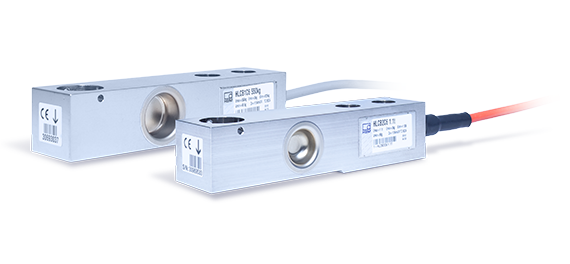

Analogue electronic output signal used in commercial and industrial small table-top to medium bench and platform weighing scales with platform sizes of up to 800x800mm and weight capacity up to 1 ton. Also used in industrial weighing solutions such as packaging machines

Used in logistics (cargo), industrial low profile and heavy-duty scales like the platform floor scales, available in capacities from 100kg up to 20 tons. Also used in industrial process weighing solutions such as tanks and silo weighing system

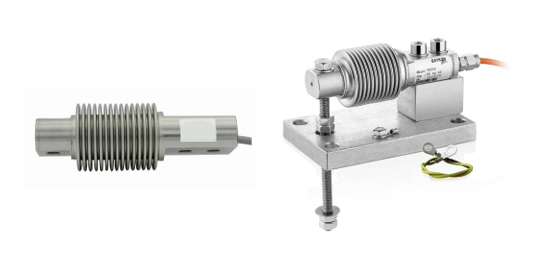

Used in belt weighing system, in-motion (dynamic) industrial process, feeders, platform scale in the high vibration environment.

Used mostly in tension force and weighing applications like hanging and industrial scales like the crane scales, available in capacities from 50kg up to 100 tons. Also used in industrial weighing solutions such as hopper, tensile, hoist weighing systems

Used in truck scales (weighbridges), large platform scales, silo & tank weighing systems, hopper scales, batching plant systems.

Capacity from 100kg up to 100 tons per load cell.

Used in high accuracy industrial weighing applications; hoppers, silo’s, platforms, industrial testing machines.

Weighbridge load cells are a group of load cells types and models used in truck scales, static weighbridges, in-motion (dynamic) vehicle weighing. The most commonly used types are double-ended share beam load cells (ball type load cell), compression type load cells, and canister load cells

the Load cells used in the platform scales are mainly two types, the single point type uses in the bench-scale that requires one load cell, and the shear beam type of load cells used in the low-profile heavy-duty floor scale that usually takes 4 load cells to make a high-capacity weighing scale

The shear beam and compression load cells and modules are what are mostly used for silo and tank weighing scale systems. The same types of load cells used for hanging hopper tanks in addition to the s-type load cells

WhatsApp us